- Options for star, ring, or daisy chain topologies.

- Operators can monitor real-time performance and network data by complying with IEEE Ethernet standards.

- Flexible network architecture compatible with ordinary Cat 5 cabling and routers simplifies network setup and guarantees all devices interact and exchange data.

- EtherNetIPTM and PROFINETTM enabled devices can provide rich data for process control, monitoring, diagnostics, and predictive maintenance.

Because EtherNet/IP™ and PROFINET use the Common Industrial Protocol (CIP™), support exists from a vast ecosystem of solution providers for industrial process automation. EtherNet/IP™ and PROFINET readily connect to a wide range of DCSs and PLCs, including:

- Allen-Bradley

- Emerson

- Siemens

- Rockwell

Due to the ability of contract manufacturers and end-users to use the EtherNet/IP™ and PROFINET protocols to:

- Cut operating costs

- Boost process efficiency, quality, yield, and output.

Brooks Instrument engineers worked with Rockwell Automation to provide an upgraded device profile that simplifies the setup and integration of the MFC into the Rockwell Automation (Allen-Bradley) PLC. The SLA5800 and SLAMf are now compatible with EtherNet/IP™ from renowned automation manufacturers.The upgraded device/add-on profile:

- Setup or edit any of the attribute tabs or parameters. The user determines which attributes are appropriate for their procedure.

- Removes the requirement for programming expertise to connect the MFC to the network.

On the SLA5800 and SLAMf with EtherNet/IP™ or PROFINET, we deliver on our promise to provide value without losing equipment space. Brooks Instrument designed EtherNet/IP™ and PROFINET directly into the mass flow controller, eliminating the need for add-on adapters or modules. The SLA5800 and SLAMf MFCs completely integrate EtherNet/IP™ and PROFINET. The EtherNet/IP™ or PROFINET equipped SLA5800 and SLAMf MFCs have the same footprint as the regular SLA5800 and SLAMf. They also link to your EtherNet/IP™ or PROFINET networks, eliminating the need for additional hardware such as gateways, analog I/O cards, or bespoke cabling and wires. All you need is standard ethernet wiring to get your device running and linked to the network.

The SLA5800 and SLAMf with EtherNet/IP™ or PROFINET have a user-friendly TCP/IP configuration. A web-based interface connects the MFC to the user's EtherNet/IP™ or PROFINET networks. Once on the network, the user can quickly identify individual MFCs, saving time if the system has several MFCs.

Intelligent and data-rich mass flow controllers, the SLA5800 and SLAMf with EtherNet/IP™ or PROFINET may improve operational efficiency in equipment automation, metrology, and maintenance.For example, limiting the upstream gas input pressure may affect MFC accuracy. The alarm data could be supplied to an operator via the built-in restricted flow alarm.

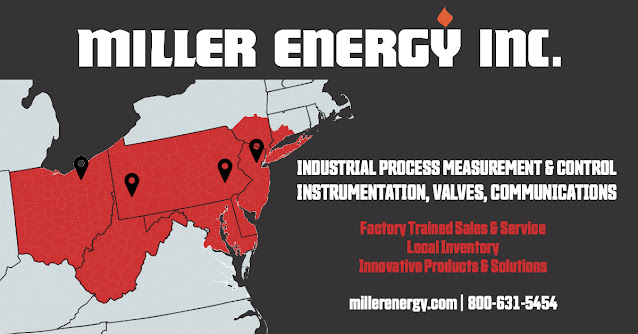

https://millerenergy.com