In an era where Internet search engines and artificial intelligence promise instant answers to complex questions, the traditional role of the industrial valve, instrumentation, and process control sales engineer faces unprecedented scrutiny. Critics argue that online resources can replace the consultative expertise these professionals provide. However, this perspective overlooks the multifaceted value that sales engineers bring to the sales cycle when specifying, applying, and supporting process control equipment. Their ongoing importance lies in their technical knowledge and ability to navigate the intricate landscapes of industrial processes, regulatory compliance, and personalized customer support.

Process control equipment forms the backbone of many industrial operations, from chemical plants to food processing facilities. Selecting the appropriate valves, sensors, and control systems requires a deep understanding of the specific application, environmental conditions, and safety considerations. While online resources offer a wealth of information, they cannot replace the tailored insights that a seasoned sales engineer provides. Sales engineers draw from years of hands-on experience to recommend solutions that align with each customer's unique needs. They consider factors such as compatibility with existing systems, scalability for future expansions, and compliance with industry standards.

Moreover, sales engineers excel in translating complex technical specifications into practical solutions. They bridge the gap between manufacturers and end-users, ensuring that the equipment meets performance requirements and integrates seamlessly into the customer's operational workflow. For example, when specifying a control valve for a high-pressure application, a sales engineer assesses the pressure ratings, material compatibility, actuation methods, and potential failure modes. This level of detailed analysis cannot be replicated by AI algorithms that lack context-specific judgment.

In the application phase, sales engineers provide invaluable support beyond the initial sale. They assist with installation guidance, troubleshooting, and optimizing the equipment's performance. Their involvement reduces downtime, enhances safety, and improves overall efficiency. Customers rely on their expertise to navigate unexpected challenges during commissioning and operation. While AI tools can offer generic troubleshooting tips, they cannot replace the nuanced understanding from direct experience with similar situations.

Supporting process control equipment over its lifecycle involves anticipating maintenance needs, upgrading components, and adapting to changing operational demands. Sales engineers cultivate long-term customer relationships, offering continuity that fosters trust and reliability. They stay abreast of technological advancements and regulatory changes, proactively advising customers on maintaining compliance and leveraging new improvement opportunities. This proactive approach differentiates them from static online resources that may not reflect the latest industry developments.

Furthermore, the human element that sales engineers bring cannot be underestimated. Building rapport and understanding customer concerns require empathy, active listening, and effective communication—qualities that AI has yet to master fully. Sales engineers can discern unspoken needs and address apprehensions that customers might not express explicitly. They provide reassurance and confidence in decision-making processes that involve significant investments and potential risks.

In conclusion, the industrial valve, instrumentation, and process control sales engineer remain a critical asset in the sales cycle despite the rise of Internet search and AI technologies. Their expertise, personalized service, and ability to navigate complex industrial environments offer irreplaceable value to customers. The digital age may provide access to information, but it cannot replicate the depth of understanding and human connection that sales engineers deliver. As industries continue to evolve, the role of the sales engineer will adapt but remain essential in ensuring that process control equipment meets the ever-changing demands of modern operations.

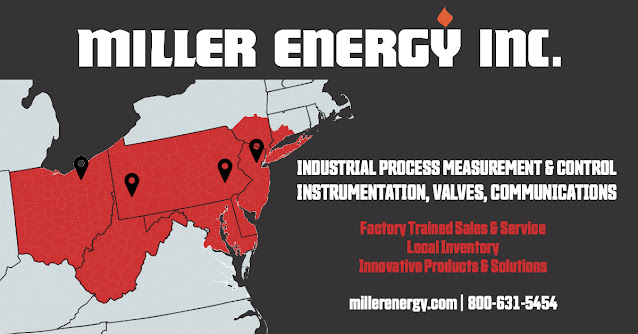

Miller Energy, Inc.

800-631-5454

https://millerenergy.com