|

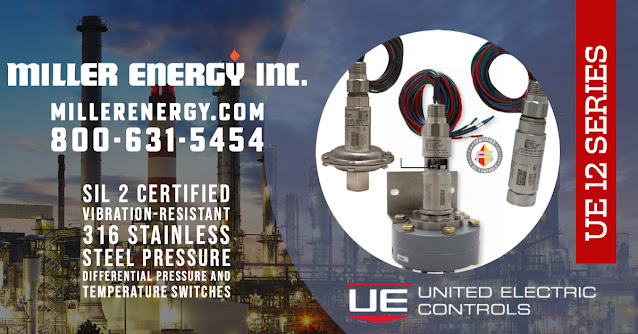

Series One Safety Transmitter and Switch

Courtesy United Electric |

Safety implementation typically is accomplished by a group that includes plant instrument engineers and technicians. They are charged with developing simple and reliable solutions that increase safety and reduce risk. Safety related events can involve the question of when to shut a process down. These decisions can hinge on the level of key process variables such as flow, level, temperature and pressure. All must be within their specified range at various locations throughout the process, whether within chemical and petrochemical plants, refineries and power plants, or other processing operations. Critical points of measurement can include anything from process vessels to eye wash stations.

For such point safety applications, a properly designed and implemented digital switch with self-diagnostics can be an important part of the answer. As an element of a multiple technology solution, a digital switch-based approach can help eliminate common-mode failures, significantly improve response time, achieve needed safety integrity levels (SILs), and simplify plant safety instrumentation.

United Electric Controls has authored a white paper entitled "Simplifying Plant Safety Instrumentation" that provides some insight into deployment of safety controls. The entire white paper is included below and will prove to be useful reading. More detailed product and application information is available from

product specialists. Combining their product expertise with your process knowledge will produce the best solutions.