A blog specializing in pressure, temperature, level and flow instrumentation, control valves, process analyzers, and all other areas of process measurement. Courtesy of Miller Energy, a New Jersey, New York, Pennsylvania, and Ohio process instrumentation Rep and Distributor.

The Importance and Uses of Variable Area Flowmeters (Rotameters) in Industrial Applications

How Does a Rotameter Work?

Importance of Rotameters in Industrial Applications

- Cost-Effective: Due to their uncomplicated design and construction, rotameters are generally more affordable than many other flowmeter types, making them a preferred choice for applications where cost is a significant concern.

- Direct Readout: Rotameters provide an immediate visual indication of the flow rate, eliminating the need for additional electronic devices or readout systems, particularly useful in environments where electronic instrumentation may be impractical or undesirable.

- Flexibility: Rotameters apply for both liquids and gases, provided the appropriate float material and tube size are selected.

- Low Maintenance: With few moving parts and no electronic components, rotameters require minimal maintenance, reducing operational downtime.

- No Power Requirement: Rotameters operate without external power sources, making them ideal for locations where power availability is a challenge.

Common Uses of Rotameters in Industry

- Chemical Processing: Rotameters are extensively used in chemical plants to monitor and regulate the flow of raw materials, intermediates, and finished products. Their ability to handle aggressive chemicals, assuming construction with compatible materials, makes them suitable.

- Water Treatment: In water treatment plants, rotameters help monitor and control the flow of water and treatment chemicals, ensuring effective treatment and efficient plant operation.

- Gas Distribution: Industries that utilize various gases, like nitrogen, oxygen, or carbon dioxide, use rotameters to monitor and regulate gas flow, ensuring optimal process conditions.

- Pharmaceuticals: Ensuring precise flow rates is crucial in the pharmaceutical industry. Rotameters help regulate the flow of solvents, active ingredients, and other fluids, maintaining the consistency and quality of drug products.

- Laboratories: Rotameters are commonly found in research and analytical labs, allowing scientists to control the flow of gases or liquids in experiments precisely.

- Food and Beverage: The food industry uses rotameters for tasks such as regulating the flow of ingredients in food processing or managing cleaning agents in CIP (Clean-In-Place) systems.

- HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, rotameters help ensure the proper flow of refrigerants and other fluids, guaranteeing system efficiency.

When Old School is Best: The Continued Relevance of Electro-Mechanical Switches in Modern Process Control

- Simplicity and Reliability: Electro-mechanical devices function on straightforward principles, such as the expansion of a bimetallic strip in response to temperature changes or the deformation of a diaphragm in response to pressure variations. These switches, having few moving parts, are inherently reliable. They don't suffer from software bugs or require firmware updates.

- Direct Control: Electro-mechanical switches can be wired directly to the control elements like solenoids, relays, or alarms, providing immediate response without needing an intermediary control system or software processing.

- Fail-Safe Operations: In safety-critical applications, it's sometimes preferable to have a direct-acting, mechanically-driven switch that can actuate an emergency shutdown or trigger alarms. These switches' inherent "on/off" nature ensures a definite state.

- Cost-effective: Electro-mechanical switches are generally less expensive than their electronic counterparts, especially for applications that don't require continuous monitoring or advanced functionalities.

- Low Power Requirements: Unlike electronic sensors that may need continuous power, these switches only consume energy when they change state, making them energy-efficient for specific applications.

- Resilience to Electromagnetic Interference (EMI): Electro-mechanical devices, being fundamentally mechanical in operation, are less susceptible to EMI, which can be a concern in industrial environments with heavy machinery and electrical equipment.

- Long Lifespan: Many electro-mechanical switches are known for their durability and long operational lifespan, mainly used within their design specifications.

- Versatility: They work in environments where advanced electronics, such as high-temperature areas or corrosive materials, might fail.

- Independent Operation: These switches do not necessarily rely on centralized control systems. This decentralization can be an advantage in scenarios where a failure in the central system shouldn't impact local controls.

- Ease of Integration: The infrastructure is built around electro-mechanical devices for many older plants and factories. Integrating newer electronic devices might require significant overhauls while continuing with electro-mechanical solutions offers seamless integration.

Miller Energy, Inc.

https://millerenergy.com

800-631-5454

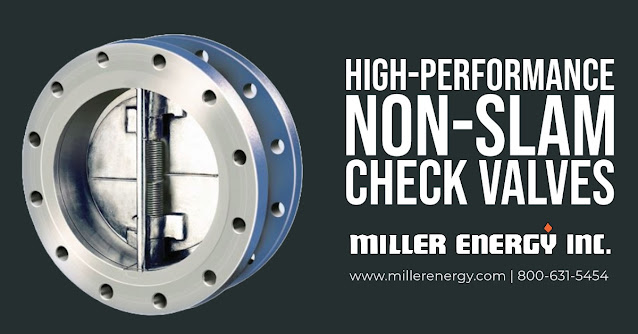

High-Performance Non-Slam Check Valves

Advantages of using non-slam check valves in industrial process applications:

Vaisala Polaris™ Refractometers: Enhancing Process Efficiency and Product Quality

- Indispensable tools in process automation.

- Boosting product quality and uniformity.

- Enhancing efficiency.

- Minimizing waste and costs.

Industrial Valve Automation Services from Miller Energy

Miller Energy, Inc. is at the forefront of delivering innovative and comprehensive industrial valve automation solutions that cater to various industries, including oil and gas, chemical, power, and water treatment. With a proven track record, Miller Energy has consistently demonstrated its ability to provide high-quality products and services that exceed customer expectations.

State-of-the-Art Technology

Miller Energy leverages the latest advancements in valve automation technology to deliver high-performance products that withstand the most demanding industrial applications. Our engineers and technicians work to ensure that every solution offers precise engineering, unparalleled reliability, and durability.

Customized Solutions

Understanding that each industrial application is unique, we offer customized valve automation services to meet the specific requirements of every application. Our team of experts works closely with customers to develop tailored solutions that ensure seamless integration with their existing infrastructure and processes.

Exceptional Customer Service

Our commitment to exceptional customer service is unwavering. From the initial consultation to after-sales support, our team provides a seamless experience. We pride ourselves on our proactive approach to addressing customer concerns and offering timely assistance to ensure your satisfaction.

Wide Range of Products

With an extensive selection of valve automation products, Miller Energy, Inc. has the ideal solution for any industrial application. Our offerings include:

- Automated Ball Valves

- Automated Butterfly Valves

- Automated Control Valves

- Automated Knife Gate Valves

- Actuators (pneumatic, electric, and hydraulic)

- Accessories (positioners, solenoid valves, limit switches, etc.)

Quality Assurance

We understand the importance of quality assurance in the success of your operations. That's why we dedicate ourselves to ensuring that our products and services adhere to the highest industry standards. Our rigorous quality control processes guarantee you receive reliable and efficient valve automation solutions every time.

Industry Expertise

Miller Energy boasts an exceptional team of industry experts with decades of experience in valve automation. Our professionals possess the skills, knowledge, and expertise to provide unrivaled guidance and support throughout your valve automation systems' design, installation, and maintenance.

Sustainability and Environmental Responsibility

As an industry leader, we are committed to promoting sustainable practices and environmental responsibility. Our innovative products and services contribute to reduced energy consumption, lower emissions, and minimized waste, allowing your organization to operate more efficiently while reducing its environmental impact.

Miller Energy is your one-stop shop for state-of-the-art valve automation services. With a focus on innovation, customization, quality, customer satisfaction, and dedication to providing the best solutions for your industrial needs. Trust in our expertise and experience to propel your operations to new heights of success. Contact us today to discuss how we can help optimize your valve automation systems.

800-631-5454

https://millerenergy.com

Thermal Mass Flow Controllers & Meters for the Harshest Environments

Thermal Mass Flow Controllers (MFCs) play a crucial role in process control applications by precisely and accurately controlling gas flow rates in various processes. They are used across multiple industries and applications to ensure stable, repeatable, and efficient process conditions. Some of the critical areas where Thermal MFCs are applied include:

- Semiconductor Manufacturing: In semiconductor fabrication processes, such as chemical vapor deposition (CVD) and plasma etching, MFCs control the flow of process gases to maintain accurate gas ratios and reactant concentrations, ensuring consistent wafer quality.

- Pharmaceutical and Biotechnology: MFCs apply in processes such as fermentation, cell culture, and gas chromatography, where they regulate the flow of gases like oxygen, carbon dioxide, and nitrogen to maintain optimal growth conditions for biological cultures or to separate and analyze various compounds.

- Chemical Processing: In chemical synthesis and reaction control, MFCs manage the flow of reactants and carrier gases to maintain the proper stoichiometry and reaction conditions, ensuring high-quality product yields and safe operations.

- Solar Cell Manufacturing: MFCs apply in processes such as thin-film deposition and chemical etching, where they control the flow of process gases to create uniform layers and achieve precise etching profiles for high-efficiency solar cells.

- Fuel Cell Development: In fuel cell research and manufacturing, MFCs regulate the flow of hydrogen, oxygen, and other gases to maintain optimal conditions for efficient energy production and long-lasting performance.

- Environmental Monitoring: MFCs are used in air quality monitoring and emissions testing systems to control the flow of calibration gases, ensuring accurate measurements and compliance with environmental regulations.

- Laboratory Research: In various research applications, such as mass spectrometry, gas chromatography, and flow chemistry, MFCs provide precise control over gas flow rates for accurate analysis and experimental conditions.

Thermal Mass Flow Controllers are essential components in process control systems, providing the accuracy, precision, and repeatability required for maintaining optimal process conditions and ensuring high-quality results across diverse industries and applications.

Brooks Instrument SLAMf Series Thermal Mass Flow Controller

The Brooks Instrument SLAMf Series Thermal Mass Flow Controller is an innovative and cutting-edge solution for accurately controlling and measuring gas flow in a wide range of industries and applications. This state-of-the-art flow controller meets the highest performance, reliability, and flexibility standards, ensuring seamless integration into your process control systems.

The SLAMf Series boasts several unique features that set it apart from its competitors. With its patented MultiFlo™ technology, users can easily configure the controller for multiple gases and flow ranges without sacrificing accuracy or requiring recalibration. This results in a highly versatile device capable of meeting the demands of diverse applications.

Another standout feature of the SLAMf Series is its ultra-fast response time, facilitated by the advanced sensor design and high-speed digital signal processing. It ensures that your processes are consistently controlled with precision, minimizing the risk of variations and improving overall efficiency.

The robust construction and corrosion-resistant materials used in the SLAMf Series make it suitable for even the most challenging environments. Its compact design allows easy installation in tight spaces, making it an ideal choice for various industries, such as semiconductor manufacturing, pharmaceuticals, chemical processing, and research facilities.

Typical applications for the Brooks Instrument SLAMf Series Thermal Mass Flow Controller include gas mixing and blending, gas delivery, process control, and environmental monitoring. With its unparalleled performance, adaptability, and durability, the SLAMf Series is the ultimate choice for professionals seeking the best in flow control technology.

Miller Energy, Inc.

800-631-5454

https://millerenergy.com