|

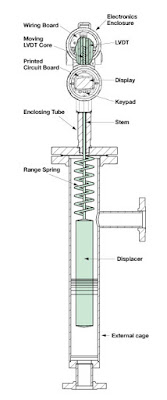

| Electronic displacer liquid level transmitter using spring technology Courtesy Magnetrol |

Magnetrol, a globally recognized leader in the design and production of level measurement instrumentation, describes the operating principle of their Digital E3 Modulevel® displacer level transmitter:

Electronic displacer level transmitter technology operates by detecting changes in buoyancy force caused by liquid level change. These forces act upon the spring supported displacer causing vertical motion of the core within a linear variable differential transformer.

The movement of the core within the LVDT generates an electrical signal which is further processed and serves as the output of the transmitter. The unit is designed to be externally mounted on a tank. Isolation valves are recommended.

The spring technology employed as a counterforce to the buoyancy of the displacer results in a stable signal that is not impacted greatly by vibration, agitation, or turbulence of the measured liquid.

The video below provides more detail, covering the features and advantages of this level measurement technology and the Magnetrol instrument. Share your level measurement challenges and requirements with a product application specialist. The combination of your process knowledge and their product application expertise will produce effective solutions.

The spring technology employed as a counterforce to the buoyancy of the displacer results in a stable signal that is not impacted greatly by vibration, agitation, or turbulence of the measured liquid.

The video below provides more detail, covering the features and advantages of this level measurement technology and the Magnetrol instrument. Share your level measurement challenges and requirements with a product application specialist. The combination of your process knowledge and their product application expertise will produce effective solutions.